In late spring/early summer 2024 we will be launching a series of themed 5S webinars.

These 5S webinars (each 2.5 hours in duration) and delivered on a monthly basis, will be structured as follows :

- Module 1 : Developing a Safe workplace.

- Module 2 : Efficiency gain through Organisation and Optimisation of the workplace.

- Module 3 : Reduced downtime through advanced asset care: “In-your-face Engineering”.

- Module 4 : Improved Quality through robust Visual management systems.

- Module 5 : Standardising the gains: Developing safe and optimised working procedures including the use of Augmented reality systems.

A summary of the key objectives and outcomes from each module can be obtained by clicking on the following link : 5S programme.

Details

This is a practical course with just one action plan generated throughout the programme!

- Another unique feature of this initiative will be the continuation of an action plan throughout the programme.

- Templates to generate actions will be provided throughout and support will be offered individually to participants.

- A prioritised action plan developed in the first module to improve safety standards will be continually developed and enhanced by ideas generated during each subsequent module.

When will these training webinars take place?

3 Sessions have been arranged as follows :

Wednesday May 8th 2024 10.00-12.30

Wednesday June 5th 2024 10.00-12.30

Wednesday July 3rd 2024 10.00-12.30

Interested?

Please register your interest using the Contact form or e-mail drjohnthomas19@gmail.com

Projects undertaken for the Digital Accelerator Team at University of Wales Trinity St. David in 2023.

Click here for a photograph of the Digital Accelerator Team.

(Click on the blue lines for further details of each project).

- In May and June 2023 we led a project with subject experts from UWTSD for Platcon plc.

This project involved the creation of AR-enabled HMI systems with the capability to use cameras to detect features, components, or equipment in the plant. Using real-time recognition of objects in the environment, operators can automatically receive real-time information, in relation to the target context, through automatic pop-up screens. The HMI screens can in turn contain dynamic project information by displaying animated variables and allowing the use of interactive objects to initiate commands.

Dr. John R. Thomas Associates Projects in 2023.

- During the 1st half of 2023 we worked with steel fabrication company Capital Topco Ltd. of Wattsville to help them realise improved efficiency through modified working methodologies. Significant performance improvements were realised and maintained on a permanent basis.

- The ultimate aim of this project is to digitise the whole data collection and performance analysis system.

Client quote : Mr. Simon Nurse : Works Manager. Capital Topco Plc.

“We’re working closely with John on OEE and Lean manufacturing principles, helping us covert our enthusiasm and OEE naivety into processes that release the potential of our equipment, processes and people. John’s wealth of manufacturing experience is apparent and his guidance is clear, logical and forward thinking; precisely our direction of travel.”

- During winter 2022/23 we delivered a series of Project Management workshops for Woodpecker flooring of Caerphilly.

Client quote : Ms. Maria Sparrow : HR and Training Manager. Woodpecker Flooring Plc.

Having worked with Dr John previously at another company, there was only one person to turn to when I was asked to arrange a Project Management course for our Management Team. Dr John’s training is so unique, due to his exceptional level of experience, plus there was an added bonus, as Dr. Rhian Thomas co-delivered the course too!

Our management team came armed with their ‘projects’ ready to apply the techniques clearly demonstrated by Dr John and Rhian over 3 separate sessions.

From the very first session, we instantly witnessed the impact the Project Management training was having on the team’s KPI’s. We observed reductions in departmental overheads; refined internal processes; improved confidence levels in the management team; teambuilding; collaboration; and the entire management team came away speaking a new ‘project management’ language.

The benefits have been immense, so thanks Dr John and Rhian for delivering an exceptional course which is adding so much value to our business as a whole.

- In June 2022 we delivered a series of Problem Solving skills workshops for Northamptonshire based logistics company Logistex.

This involved the deployment of the 7 tools of quality in a dynamic practical way to address their current challenges.

Client quote : Ms. Theresa Powderly : Quality Manager. Logistex Plc.

“Dr John delivered problem solving training to myself and some colleagues. He is a very knowledgeable and passionate individual. His delivery style is exceptional and had us all engaged for all the sessions. We are now able to use the skills we have developed in problem solving within Logistex and will be booking more training in the coming months.

We are so excited to be on our CI journey and look forward to more time with John to help grow our skill set. Thanks”.

- In April 2022 we were commissioned to run a workshop on Improving Productivity in small businesses (click for details) at Aberinnovation in Aberystwyth.This session was specifically targeted at small companies in the food-producing, agritech and allied sectors.

- In March-May 2022 we were engaged by a company in the building products industry to develop reconfigured processes for their main product lines. This project identified significant improvement opportunities based on new technologies.

Client quote : Mr. Dominic Thew : General Manager, Atal Plc.

“Dr Thomas has been amazing in helping our company increase productivity in the warehouse/factory floor. With his help we have managed to source a machine which will save countless hours in production, with that helping us secure bigger projects as we will be able to keep up with demand.”

- In March and November 2022 we ran workshops on Innovation management for a group of companies in the Blaenau Gwent area. This was run under the auspices of the Vista programme co-ordinated by the University of South Wales.

- In February and October 2022 under the Vista programme we ran a series of workshops on Improving Efficiency for Small Busineses.

- In summer/autumn 2021 we co-ordinated a project developing a pilot plant for a medical plastic waste recycling company. This project involved extensive deployment of F.M.E.A. techniques.

Client quote : Dr Alvin Orbaek White : Trimtabs Ltd.

“John was very helpful in teasing out the assumptions in the process and his continued questions raised important issue that will need to be dealt with by the relevant professionals in our team.

The FMEA that was carried out was able to highlight several strengths and weaknesses in the design process and now that we are aware of those we will be able to dedicate time and energy to specific goals.”

Before the pandemic struck…

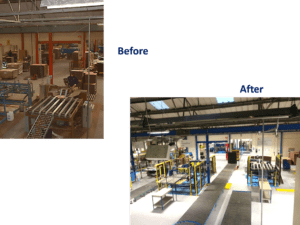

- We co-ordinated a 5S workplace organisation programme and a Value-stream mapping project for Smurfit Kappa at their Mold, North Wales, Corrugated packaging plant.

- Undertook a Value-stream mapping project for traditional building products company Ty Mawr Lime of Brecon, during which significant cost-reduction opportunities were identified.

- Co-ordinated a 5S project for Chivas Bros. of Dunbarton Scotland – a leading player in the Scotch Whisky Industry.

- We developed and delivered a course on Value-Stream Mapping for the Engineering faculty at University of Wales Trinity St. David.

- We delivered Time Management courses for key team leaders at market-leading Cruise specialists Cruise Nation Ltd.

- Led a Lean programme for leading chimney manufacturers Brickfab at their facility in Pontypool.

- Throughout 2018 to 2020 we undertook regular business diagnostic studies and developed improvement programmes for a myriad of SMEs on behalf of Enterprise Professional Services Ltd. as part of the Welsh Government Innovation support scheme.

- Led a 5S workplace organisation programme for Roberts of Port Dinorwic who develop and produce quality, award-winning prepared dishes at their facility on the banks of the Menai Strait in North Wales.

Client quote : Mr. Martin Topps, HR Manager, Roberts of Port Dinorwic.

“We were introduced to 5S methodology by Dr. John Thomas of Dr. John R. Thomas Associates consultancy. The project is in its early stages and is now starting to gather momentum. The results are evident and are having a positive impact across the factory.

We are regularly audited by our customers and we hope that as well as improving safety and efficiency, we hope that we have a positive impact on our customers.”

And previously…

- Dr. John R. Thomas Associates have designed and led an extensive Lean manufacturing improvement project for the UK’s leading packaging manufacturer D.S.Smith Packaging at 24 locations throughout the UK. These projects make extensive use of World Class manufacturing techniques such as Workplace Organisation (Including co-ordinating an extensive 5S programme throughout the company), Quick Changeovers (S.M.E.D.) , Total Productive Maintenance and Value-Stream mapping.

Client quotes …

From: Mr. Brian Wark, HR Director DS Smith Packaging

“Dr. John Thomas has worked for DS Smith for over 20 years initially as an employee and latterly as a consultant, supplying operational improvement services such as Lean, 5S, Manufacturing Audits and various other training and consultancy services.

During his time with DS Smith, John transformed many of our sites into beacons of excellence, working with local managers and crews, building engagement and commitment so that the improvements have been sustained.

I would have no hesitation in recommending John for any business/operational transformation projects where engagement and pragmatic solutions are key.”

From : Mr. Richard Caunt U.K. Technical Director D.S. Smith

“I have known John for nearly 20 years and have always found him to be a highly professional specialist in manufacturing techniques. John doesn’t just tell you how – he has delivered hands-on training and support to develop our teams across the whole of the UK business.

This has not only taught our employees to use tried and trusted methods, it has also helped with developing the culture where everyone wants to find better ways of doing things.

John has recently been training in over 24 of our key sites in the UK delivering 5S, SMED and other lean manufacturing techniques. Much success has been achieved with a standard and consistent approach being used in all plants.

John is well respected by people at all levels in the business and his friendly but at the same time tenacious approach delivers results.”

From : Mr. Graham Coles, Plant Manager, D.S. Smith Kettering.

“Dr John’s programmes are a very easily accepted Paradigm within an engaged workforce, his concept can be tailored to bring out the best in individuals and teams, John always uses techniques to suit his audiences”.

From: Mr. Peter White, M.D. Ralegh Integrated Solutions.

” Over the years Dr John Thomas has helped us at Ralegh Integrated Solutions to achieve a very high level of Work place organisation through encouraging us to look at what we do, ask if we need to do it and if it could be done better? John has the distinct knack of getting people engaged at any level within the organisation through his obvious knowledge and determined personality”.

A selection of previous projects undertaken:

- A extensive programme of Project management courses run for novelty packaging company Bonbon Buddies and for International frozen foods company Birds Eye.

- The Birds Eye courses involved training a wide range of Project managers from across their European operations.

Client quote ..

Maria Sparrow, HR Manager, Bon Bon Buddies

“Bon Bon Buddies was founded in 1993 and is today recognised as Europs leading provider of character confectionery to over forty countries worldwide. The company has developed its own brand confectionery and also boasts an exciting portfolio of licenses including Disney, Spiderman , Barbie and One Direction to name but a few.

During late 2014 and early 2015 Bon Bon Buddies sought training that would help up-skill their workforce, reinforce previous training, promote career development and ultimately gain competitive advantage.

Dr John R. Thomas delivered a Project Management and FMEA course to almost half of our UK based employees. Prior to John delivering this training he took the time to understand BBB’s business strategy and more importantly our desired outcome. John’s wealth of knowledge and experience was reflected in the exemplary feedback received from all employees who attended these courses.

The impact of the training John facilitated resulted not only in an improvement of project management techniques of those who underwent the courses, but can be seen across the business as a whole.”

- A Lean programme run for leading window and door manufacturers Euramax at their facility in Barnsley.

Client quote ..

Mr. Ken Wilson Managing Director Euramax Solutions Limited

“As I have moved from business to business I have always used John to introduce 5S and other World Class Manufacturing techniques. John has the ability to explain the concepts in an easy to understand manner, usually aided with photos and real life examples. John’s approach is very practical and I have always seen immediate results. On repeat visits John has always kept himself updated and it’s a real advantage having John’s experience to learn from. My operations managers usually can’t wait for the next tips and ideas. For anyone at any level looking for the next efficiency improvement, I would have no hesitation to recommend John.”

- Following an extensive Lean Leadership and Project Management programme run for Peter’s Foods in Caerphilly ; Dr John R. Thomas Associates were asked to help co-ordinate a major project whereby Peter’s have now become the primary source of supply of own brand savoury products for J Sainsbury Plc.

Client quote ..

Mr. Mike Grimwood, Managing Director, Peters Food Services.

“Firstly and most importantly I should like to thank you (belatedly) for the second project management segment. Without exaggerating I am already convinced that it has been the single most beneficial series of training workshops I have seen in my years in business. The guys have caught the concept and have been practicing application from day 1.

Interestingly in Food Service where additional sales contracts requiring additional routes has been a key agenda item; or ranging is being reviewed we’re off to a flying start.

So again many thanks. Mike.”

- Dr. John R. Thomas Associates co-ordinated a strategy development programme for electronics manufacturer DBK Technitherm.

- Total Productive Maintenance and Quick changeover programme run for Texturing Technologies Ltd. at the Tata Steel Site at Margam.

- In response to major changes to the market requirements that the company have experienced, Dr. John R. Thomas Associates ran a major 5S/SMED Changeover time reduction programme for the UK’s leading plastic container manufacturers RPC : This has resulted in a significant capacity increases, service level improvements and profit generation to the client due to the considerable time and cost savings generated by the project.

- Lean programme run for high quality printers and bookbinders Cambrian printers.

- Lean manufacturing improvement programme run for Optical lens specialist manufacturers Lenstec Optical in Caerphilly.

- Lean manufacturing improvement programme run for Altron Communications Equipment Ltd.

- Co-ordinated 2 Lean projects in the supply chain of the Scotch Whisky Industry.

- A Process analysis project to develop better control systems for the key process variables of the Jaffa cake manufacturing line at Burtons foods has resulted in significant quality and performance improvements through use of techniques such as Failure Modes and Effects Analysis (F.M.E.A.) and POKA YOKE (Fool-proofing).

- Other Lean projects completed for Safety Letterbox, Excel Engineering, Carlisle Brake products, Labelgraphics, De La Rue and Northern Automotive Systems