Embracing the opportunities offered by Industry 4.0 technologies.

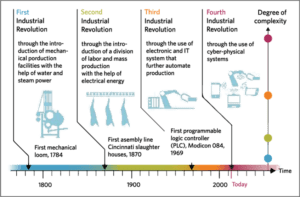

Coined by the World Economic Forum (WEF) in 2016, the Fourth Industrial Revolution, also referred to as Industry 4.0, is the fourth major industrial era, since the initial Industrial Revolution of the 18th century.

The Fourth Industrial Revolution can be described as a range of new technologies that are fusing the physical, digital and biological worlds, and impacting all disciplines, economies, and industries.

Click on both graphics to expand.

Click on both graphics to expand.

We have constructed a programme to help organisations exploit the benefits of deploying a range of developing technologies.

These technologies are challenging existing production models by enabling secure, plant-wide connectivity between machines, people, information and business processes.

Have a look at some of the summaries below to get an introduction to these technologies.

Initially we examine these new technologies, and predict how they could benefit individual organisations:

- The Internet of Things (IoT).

In 1982, a modified Coke machine at Carnegie Mellon University became the first connected smart appliance, able to report its inventory and whether newly stocked drinks were cold.

Fast forward a few decades, and we are living in a world where there are more connected things than humans.

Business Insider Intelligence projects that there will be more than 55 billion IoT devices by 2025, up from about 9 billion in 2017

IoT is a network of interconnected devices, machines, vehicles, objects and even living beings that have unique identifiers and the ability to share data without human involvement.

Organizations that can capture IoT data and transform it into insight using real-time AI will see real business value:

- Efficiency gains as AI makes complex decisions and automates manual tasks.

- Cost reductions as AI optimizes processes to reduce marginal transaction costs.

- Faster innovation life cycles, as AI makes it easier for organizations to start, scale and grow their operations.

- Better products and faster customer service, such as bots powered by speech recognition.

2. Advanced data collection and analytics including Artificial Intelligence.

The amount of data generated by businesses and customers is growing at an exponential rate. As computational power intensifies, firms are able to accumulate, mine and analyse vast and complex datasets to better mitigate risk, increase efficiency, understand market needs and grow new income streams.

Computers cannot be taught to think for themselves, but they can be taught how to analyse information and draw inferences from patterns within datasets.

And the more you give them – computer systems can now cope with truly vast amounts of information – the better they should get at it.

AI is the science of training systems to emulate human tasks through learning and automation.

With embedded AI, machines can learn from experience, adjust to new inputs and accomplish specific tasks without manual intervention.

Facial recognition and speech recognition are all applied uses of AI.

The most successful versions of machine learning in recent years have used a system known as a neural network, which is modelled at a very simple level on how we think a human brain works.

- Human-machine collaboration.

Robots that can work safely alongside humans are entering the realm of reality – and this development is set to transform work environments sooner than most companies imagine.

Thanks to visual analysis, enhanced context awareness and machine learning, analysts predict that robots will work alongside humans in the front-line – performing more complex tasks with increased agility. These smart machines will be able to anticipate needs and meet them, instead of only carrying out set tasks. The role of drones in logistics and inspection will also be examined.

Industrial robots require expert programming and training to perform tasks, so companies need to hire experienced engineers and programmers to oversee the installation of robots.

However, in recent years a new method of training robots has been implemented – the no-code or low-code programming.

It allows employees with less coding experience to configure a robot using visual modelling and drag-and-drop user interfaces.

Due to the easy-to-use format of no-code and low-code platforms, robots can also be reprogrammed for different jobs by just adjusting their arm.

While companies would once require multiple robots, now a simple adjustment can be made by a non-technical person, saving companies time, space and money.

4. Additive manufacturing (AM).

Known as additive manufacturing, 3D-printed objects are created from a digital file and a printer that lays down successive layers of material until the object is complete.

Each layer is a thinly sliced cross-section of the actual object. It uses less material than traditional manufacturing.

Most materials used in 3D printing are thermoplastics—a type of plastic that becomes liquid when heated but will solidify when cool and not be weakened.

However, as the technology matures, researchers are finding new materials—even edible—that can be 3D printed.

Metal 3D Printing holds a unique position in modern-day product development. It allows for the direct manufacturing of complex end-use parts reducing costs and lead times.

3D bioprinting is a technology where bioinks, mixed with living cells, are printed in 3D to construct natural tissue-like three-dimensional structures.

3-D printing technology is advancing fast, enabling the production of solid objects from a digital data source in a range of locations. The benefits for manufacturers include the ability to create prototypes quickly and yield small, customised, finished batch sizes, or even individual products, with fewer resources.

Quick, production-ready prototypes are essential for efficient manufacturing and speed to market.

Modeling/simulation scenarios early in the design process help determine the best possible design for prototyping.

Previously unimaginable structures can now be created, sometimes from completely new materials.

Design-engineered items produced by AM allow product with greater internal complexity.

The ability to include internal lattices in AM structures is of particular benefit to aerospace, healthcare and automotive light-weighting initiatives.

- Cloud-based data storage.

Developments offered by Industry 4.0 technologies are transforming the Supply Chain.

IoT-enables sensors and data analytics give manufacturers insight into the entire supply chain and production process.

This level of visibility combined with AI and machine learning capabilities means that supply chain optimization can be achieved in real time.

Software as a Service (SaaS) based apps. are stored on cloud-based servers, which are much less expensive, much quicker to update and scale, and don’t take up any valuable space. This difference can mean a significant saving in terms of total cost of ownership (TCO). Their impact on improving the effectiveness of the supply chain using ERP systems will be examined.

6. Extended Reality (XR) techniques.

XR incorporates, among other things, the related technologies of augmented reality (AR) and virtual reality (VR).

AR superimposes digital data on the real world, either through mobile devices like tablets or special head-mounted displays (HMDs).

VR uses HMDs to contain the user in a purely digital world.

Both technologies offer a thrilling glimpse into a future that blurs the line between the physical and digital worlds.

One other term is often used in the context of XR: mixed reality (MR).

Augmented Reality Systems:

Isolated applications of AR have been around for decades, but only recently have the technologies required to unleash its potential become available.

AR transforms volumes of data and analytics into images or animations that are overlaid on the real world.

Today, most AR applications are delivered through mobile devices, but increasingly delivery will shift to hands-free wearables such as head-mounted displays or smart glasses.

Wearable AR devices for factory workers that superimpose production-assembly or service instructions are being piloted at thousands of companies. AR is supplementing or replacing traditional manuals and training methods at an ever-faster pace.

Traditional pages on flat screens—have a major limitation – they require people to mentally translate 2-D information for use in a 3-D world.

That isn’t always easy, as anyone who has used a manual to assemble flat-pack furniture knows.

By superimposing digital information directly on real objects or environments, AR allows people to process the physical and digital simultaneously, eliminating the need to mentally bridge the two.

That improves our ability to rapidly and accurately absorb information, make decisions, and execute required tasks quickly and efficiently.

7. 5G Networks:

The demand to handle a varied stream of data from inter-connected devices at a quick speed makes the 5G network crucial to the advancements of the 4th Industrial Revolution.

The pandemic made it clear how important 5G is to enable the transformation to Industry 4.0 and created new demand for stable wireless networking.

5G networks offer increased predictability, better coverage, and the possibility to combine local and global connectivity.

5G networks will serve as critical infrastructures to accelerate the digitisation, automation, and connectivity to machines, robots, and transport solutions.

This goes beyond connecting the factory but also connecting the whole supply chain and the whole lifecycle of a product.

A private network can guarantee full coverage in an operational area, both indoors and outdoors as required, as well as in remote locations where public networks are not available.

8. Cybersecurity:

Whereas smart factories promise to improve quality and efficiency in manufacturing, as well as cutting response times, they create new points of cyber vulnerability.

Manufacturers are not as mature as the financial services sector, which has had these attacks for a number of years and is therefore ahead of the curve in terms of its protections.

They are vulnerable to attacks on several fronts:

1.From a ransomware perspective, manufacturers are quite exposed to time-driven critical processes : manufacturers are therefore perceived to be more prone and therefore more likely to pay a ransom.

2.Industrial companies are often reliant on older technology to run the machinery in their manufacturing operations —challenges arise when this operational technology is then connected to the company’s corporate IT infrastructure.

Because every touchpoint in an operation is connected and digitized in Industry 4.0, there is an extra need for robust cybersecurity. Machinery, computer systems, data analytics, the cloud, and any other system connected via IoT should be protected.

We then go on to look at:

- The opportunities for exploiting these opportunities.

We have developed a diagnostic tool for prioritising how organisations can expoit the opportunities offered through utilising these technologies.

With so many technologies available, it can be difficult for companies to identify which ones will be right for their particular business: we try and help them prioritise what methods are best suited and to implement appropriate solutions.

- Wider societal implications.

We will also help the company to examine and plan to mitigate the broader human implications of these new developments, particularly their impact upon lower skill occupations within the workforce.