Are you sweating your assets? : MAINTENANCE BEST PRACTICE (T.P.M.)

What is Total Productive Maintenance (TPM)?

It is maximising throughput capacity by improving machine uptime.

The concept of TPM is built around the idea that maintaining equipment and systems should not only be the responsibility of the maintenance department but should involve all employees, from top management to frontline operators. This approach ensures that all employees take ownership of the machines and equipment they use, leading to better usage and care, and ultimately, higher productivity.

One of the main benefits of TPM is the improvement in productivity. This is achieved through the reduction of machine downtime, which results from proactive maintenance activities. By keeping machines in top working condition, breakdowns are avoided, and the production process can run smoothly and efficiently.

Furthermore, by involving all employees in the maintenance process, TPM promotes a sense of ownership and responsibility among the workforce. This leads to improved machine handling and operation, further enhancing productivity.

Reducing unplanned breakdowns is one of the most cost-effective philosophies of Lean Manufacturing.

Implementing Total Productive Maintenance

Implementing TPM in an organization requires a structured approach. It involves several steps, starting with the preparation phase, followed by the introduction of the TPM principles, and finally, the consolidation and institutionalisation of the TPM practices.

What Questions do we need to ask at the start of the project?

- How effective is the equipment?

- How much capacity is being wasted and how much is this costing?

What is the Goal?

To decrease the total downtime in order to increase machine capacity.

What are the benefits?

Proper maintenance programmes:

- Keep equipment running for longer;

- Reduce unscheduled down time;

- Realise significant cost benefits;

- Makes life less stressful.

How the TPM course is structured :

Click on the summary below for a taster of the course content.

UNIT 1 :

The basis of modern Maintenance practice.

Maximising throughput capacity by improving machine uptime is one of the most cost-effective philosophies of Lean manufacturing.

Initially we get the attendees to ask some basic questions…

• How effective is my equipment?

• How much capacity is being wasted through poor equipment care?

• How much is this costing me?

This initial module will address the following issues :

• T.P.M.? …..What can it offer?

• Criticality analysis as a tool for identifying what parts of our equipment are vulnerable.

What is Criticality analysis?

A technique whereby each element of a process is accorded a score based on how vulnerable it is to breakdown.

This score is calculated based on :

- How likely that breakdown will occur

- The cost of repairing the breakdown

- The likely delay before the breakdown is repaired

Efforts are then made to reduce this score using the techniques outlined below.

Criticality Group exercise:

Delegates will be divided into groups for a Criticality analysis exercise evaluating the vulnerability of their equipment.

As such, this initial session will involve training using visual images of good and bad practice and practical exercises focusing on the target area (Ideally the attendees own specific work area).

The key outcome of this training is to provide the attendees with an understanding that there exists a range of simple but very powerful tools for getting the best out of their equipment and thereby realise significant cost savings.

UNIT 2 :

Advanced asset care : In-your face Engineering.

This unit is designed to sit in-between the basic 5S workplace organisation techniques and the more resource-demanding Productive Maintenance approaches.

It is designed to generate quick low cost/no cost improvement ideas generally based on visual management techniques.

How many cheap- to-introduce maintenance best practices can you spot in the following photographs?

Lean concepts to be trained in this session…

• Marking the proper operating settings and ranges on gauges.

• Effective storage and management of lubricants.

• Inserting see-through windows on covers of critical equipment to allow their condition to be monitored.

• Marking the proper direction of rotation on motors.

• Labeling replacement belt, filter, and chain sizes.

• Introducing retractable lines to ease access to services.

• Preventing mistakes by effective dial labeling.

• Refusing to tolerate electrical short-cuts.

• Colour-coding set-up and changeover parts for specific jobs.

• Colour-coding pipes and air lines (and their connections) to prevent mistakes from happening.

• Labeling pipes to indicate what they contain and their direction of flow.

• Labeling electrical and electronic wiring and devices to aid trouble-shooting.

• Match-marking nuts and bolts to visually indicate that proper tightness is being maintained.

Followed by Group exercise:

Delegates will be divided into groups for an exercise evaluating the current condition of visual asset care systems deployed in their workplace.

Each attendee will be required to carry out (as part of a team) using a standard visual asset care audit template a (accompanied) survey of their area to identify the opportunities that exist. They will then be required to draw up a prioritised action list.

The improvements identified will be incorporated into an Excellence model action plan.

The key outcome of this training is to provide attendees with an understanding that there exists a range of simple, low cost but very powerful tools for quickly getting the best out of their equipment and realising major cost savings and quality/safety gains.

UNIT 3 :

Predictive and Preventive Maintenance.

Three major subjects are covered in this unit:

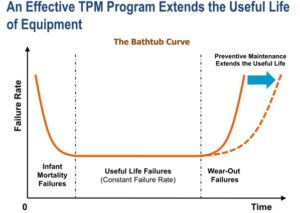

1. Implementing a Preventive Maintenance (PM) system.

“A schedule of time-based, planned maintenance actions aimed at the prevention of breakdowns and failures.”

Time Based Maintenance is best used when the failure mode is age-related and has a clear wear out limit.

Benefits:

• Increases life of equipment

• Reduces failures and breakdowns

• Reduces down time

• Decreases cost of replacement

We will examine techniques that increases the life of equipment, and helps it run more efficiently. For example:

• Regular oil changes

• Regular greasing of key components

• Changing filters on a planned basis

• Belt tightening on a planned basis

2. Developing a Spares Strategy.

A spares strategy should be developed that considers :

i. Is the customer compromised if such a spare is not available?

ii. On a bottleneck machine how much sales volume would be lost if such a spare is unavailable.

iii. What is the lead time on (delay in obtaining) such a spare?

3. Implementing a Predictive Maintenance system.

Condition Based Maintenance – An equipment maintenance strategy based on measuring the condition of equipment in order to assess whether it will fail during some future period; and then taking appropriate action to avoid the consequences of that failure.

This yields the following benefits:

• A cheap and effective ‘Health Check’ for machinery

• Minimal downtime is required to undertake these checks

Condition based maintenance can significantly extend the service life of equipment and components.

Three methods of Predictive Maintenance will be examined:

• Thermographic survey

• Oil condition analysis

• Spike energy measurement (Vibration analysis)

UNIT 4 :

Developing an Asset Care programme.

Putting all we have learnt above together into a coherent plan.

Based on the actions highlighted in the Excellence model we are now in a position to put together a clear Asset care plan with defined procedures.

Clear, safe asset care procedures are the cornerstone of reliable equipment :

1. They provide an agreed, defined reference standard.

2. It makes People look at What and Why they do things: perhaps for the first time!

3. They minimise misunderstanding and miscommunication.

4. It provides a vehicle for long running disagreements to be aired.

5. It allows for a line to be drawn : “this is what is inviolable!”

6. They provide an excellent training aid.

7. It allows for possible improvements to be suggested in a structured form.

Getting the Team to develop an Asset care schedule can be one of the most valuable and beneficial exercises for ensuring Equipment reliability on a continuous basis.

Followed by Group exercise:

Each attendee will be required to (as part of a team) generate the first draft of a Asset care schedule for their process (or review the current document is one already exists).

• The team then reviews this draft.

• Any procedure improvements are agreed.

• Further review until consensus reached.

• Incorporating as many POKA-YOKE mistake-proofing ideas as possible into current working practices.

• Any ideas for process improvement are recorded and incorporated into the Excellence model action plan.

• The tasks are detailed and systematically broken down into their respective component skill sets

• Training needs analyses are developed for each skill set.

In this way a detailed analysis is undertaken of the tasks required to care for a machine in in the right way.

Emphasis is put on incorporating as many photographic instructions and XR (see below) techniquesas possible to re-enforce the documents: thus re-enforcing the Visual and Kinaesthetic (Learning by doing) learning methods emphasised in this programme.

UNIT 5 :

Bringing Maintenance Best Practice into the world of Industry 4.0!

The use of Extended Reality (XR) techniques.

XR incorporates, among other things, the related technologies of augmented reality (AR) and virtual reality (VR).

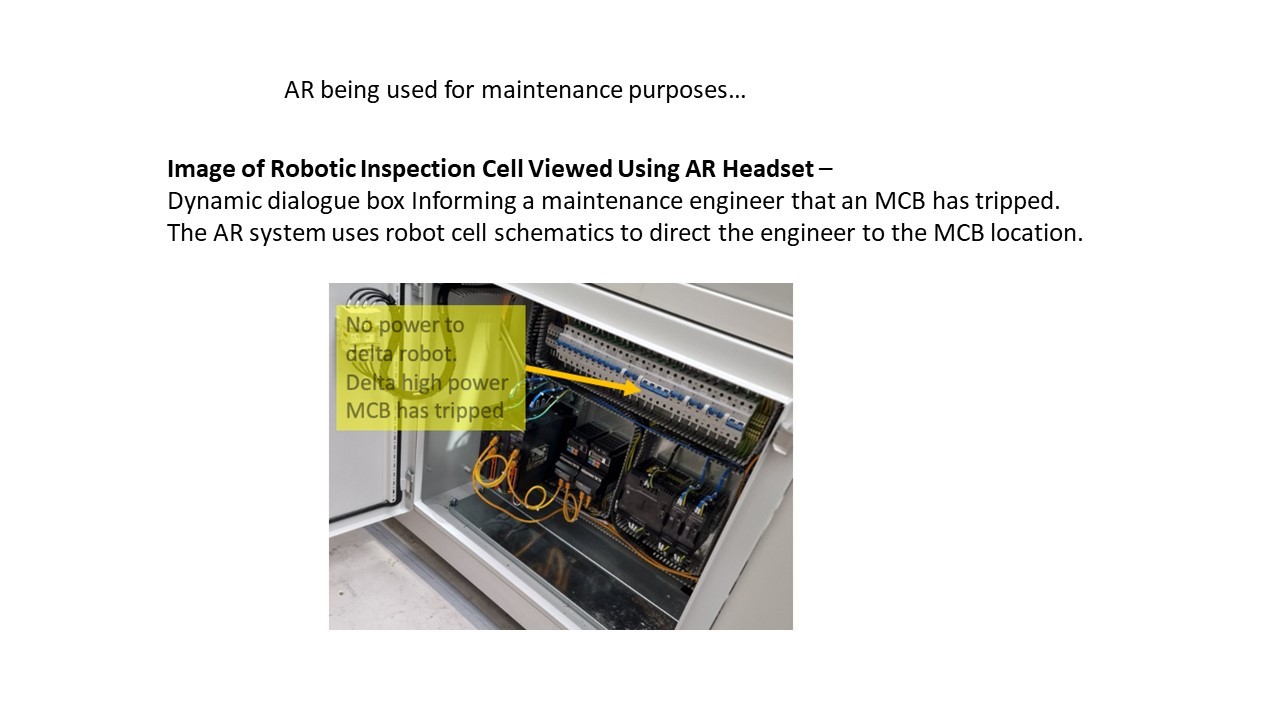

AR superimposes digital data on the real world, either through mobile devices like tablets or special head-mounted displays (HMDs).

VR uses HMDs to contain the user in a purely digital world.

Both technologies offer a thrilling glimpse into a future that blurs the line between the physical and digital worlds.

One other term is often used in the context of XR: mixed reality (MR).

Using Augmented Reality Systems for managing Maintenance systems:

AR transforms volumes of data and analytics into images or animations that are overlaid on the real world.

Today, most AR applications are delivered through mobile devices, but increasingly delivery will shift to hands-free wearables such as head-mounted displays or smart glasses.

Wearable AR devices for maintenance workers that superimpose service instructions are being piloted at many companies. AR is supplementing or replacing traditional manuals and training methods at an ever-faster pace.

Traditional pages on flat screens—have a major limitation – they require people to mentally translate 2-D information for use in a 3-D world.

That isn’t always easy, as anyone who has used a manual to assemble flat-pack furniture knows.

By superimposing digital information directly on real objects or environments, AR allows people to process the physical and digital simultaneously, eliminating the need to mentally bridge the two.

This improves our ability to rapidly and accurately absorb information, make decisions, and execute required tasks quickly and efficiently.

Complicated 2-D schematic representations of a maintenance procedure in a manual, for example, become interactive 3-D holograms that walk the user through the necessary asset care processes.

Little is left to the imagination or interpretation.

This is particularly relevant to managing maintenance practices.