Can you make it at a profit?

Understanding your PROCESS CAPABILITY

What is Process Capability?

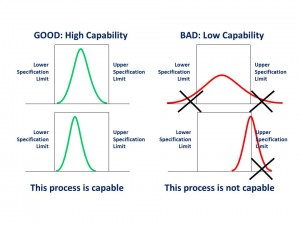

- Process capability measures the ‘goodness of a process’ – comparing the ‘voice of the process’ with the ‘voice of the customer’.

- The voice of the customer here is the specification range (tolerance).

- It is calculated by the proportion of output that can be produced within product specification.

How is this measured?

This is measured by the proportion of output that can be produced within product specification using two measurement parameters :

- Cp – this is the best indicator of potential process capability because it assumes a stable and on-target process.

- Cpk – is an indicator of actual process capability. It takes into consideration if the process is off-target.

What is covered in this course?

- What is Process Capability?

- ‘The voice of the customer’ – specification Limits.

- Variation from target – what causes this?

- The Normal distribution.

- Standard deviation and 6 sigma.

- ‘Tampering’ with a process.

- Special cause variation.

- Process Capability Indices : Cp and Cpk.

- Process Control charts.

- The movement towards ‘6 sigma’.

Click on the summary below for a taster of the course content.