Innovation management

New Product and Process Design and Development

In this unit we investigate the tools that organisations need to introduce to allow them to implement a structured but dynamic Innovation management process.

We examine :

Element 1 : Product Development

- Effective product and service design and its strategic impact on organisations.

- The key stages in the product development process.

- The importance of Cross Functional Concurrent Product Design.

- Techniques for customer delight by reducing product and service variability:

- Kano Model (The 3 levels of customer expectations)

- Taguchi Methods (Robustness through design)

- Poka-yoke (Fail-proofing)

- Quality Function Deployment : (House of Quality)

- Kano Model (The 3 levels of customer expectations)

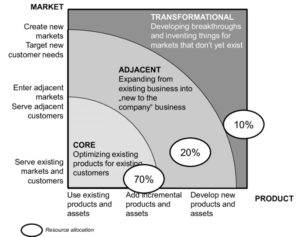

- Different types of Innovation.

- Open innovation of new ideas by applying :

- Outside-in processes

- Inside-out processes

- Coupled processes

- An introduction to Disruptive Innovation (click for short presentation).

- Protecting intellectual property.

- Implementing a structured but dynamic innovation management process.

- Using break-even analysis as a tool in selecting between alternative products.

- Ecodesign, green design and environmental design : embracing the circular economy.

- Industry 4.0 and the opportunities for Remanufacturing.

Click on the link below to reveal the differing approaches to innovation.

Element 2 : Process Development

- Identifying different types of processes and explaining their characteristics.

- The 4V’s model of process characterisation and their impact on final product cost.

- Understanding the issues which impact upon the design of product and service processes.

- Linking Product Design & Process Selection to the product life cycle.

- Design for Manufacturing (see details in Lean Tools section).

- Designing Processes to match customer demand profiles:

- Make-to-stock strategy

- Assemble-to-order strategy

- Make-to-order strategy

- Implications of a hybrid approach

- Operational Layout considerations:

- Fixed position (Project)

- Process Orientated (Batch)

- Cell layout (Flexible Batch)

- Product line (Continuous)

- Process design for the circular economy.

- Fixed position (Project)

- Types of plant configurations and their complexities : “A,” “V,” “T,” and “I” configurations.

We have found that delivering these modules in a series of 2 hour slots is the most effective mode of delivery.

After each module, the attendees are required to undertake exercises relevant to the techniques they have been taught.