5S Training Workplace Organisation

Dr. J. R. Thomas Associates uniquely deliver 5S training in a series of progressive modules.

Introducing 5S in a modular way allows companies to manage their 5S programme in a way that suits their exact needs.

The timing of the next phase in the programme will be dependent on completion of actions identified in the previous module, thus allowing companies to progress at a rate that suits them.

Significantly, not everyone needs to be put through all the modules.

Standard training packages for all staff for example, could mean commitment to just 2 of the initial modules.

On the other hand, highly skilled individuals and initiative leaders could be put through all of the modules.

In this way :

Companies can design an unique 5S training programme that meets their exact needs and progress at a pace that suits their exact situation.

Modules are structured as follows :

- Module 1 : Developing a safe workplace.

- Module 2 : Efficiency gain through Organisation and Optimisation of the workplace.

- Module 3 : Reduced downtime through advanced asset care: “In-your-face Engineering”.

- Module 4 : Improved Quality through robust Visual management systems.

- Module 5 : Standardising the gains : Developing safe and optimised working procedures.

A summary of the key objectives and outcomes from each module can be obtained by clicking on the following link : 5S taster

A training session on a shop floor…

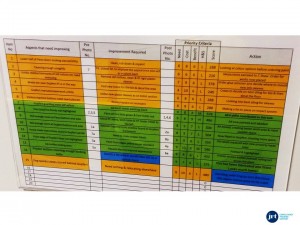

Just one action plan throughout!

Another unique feature of this programme will be the continuation of an action plan throughout the programme.

The prioritised action plan developed in the first module to improve safety standards in the target area will be continually developed and enhanced by ideas generated during each subsequent module.

In this way, a consistent improvement document is constantly updated with new ideas and managed by the team from start to finish.

How will we provide this service ?

Increasingly, client requirements are for our support courses and mentoring to be delivered as a series of 1 or 2-hour on-line webinars, delivered at a time and frequency to suit their convenience.

We believe this to be the most efficient and cost-effective mode of delivering training and support – particularly in these trying times.

We have the experience and specialist skills that enable our courses and support initiatives to be delivered using both traditional methods and the latest on-line and multi-media tools.

These can take the form of :

- Live broadcast sessions.

- Webinars.

- Group tutorials.

- Self-study web packages.

- Licenced downloads.

… all tailored to the client’s exact needs and ability to free up people for training.

The key objectives and outcomes from each module are :

UNIT 1 :

Developing a safe workplace.

Safety management is the one non-contentious factor we can use for driving improvement initiatives: the W.I.F.M. (What’s in it for me!) factor.

The key outcome of this phase of the programme will be to :

1. Highlight the link between Safety and Performance in the workplace to encourage the attendees to use these concepts to come up with their own prioritised improvement plan.

2. Understand the importance of Auditing and evaluating the Safety standards prevalent in their work area.

3. Provide a ‘car parking’ flip-chart for areas that need to be addressed immediately after the workshop.

As such, the session will be a combination of training using visual images of good and bad practice and practical exercises focusing on the target area (Ideally the attendees own specific work area).

Lean concepts to be trained in this session :

- Awareness of ongoing safety concerns.

- Storage and access to firefighting equipment.

- Access & location of emergency exits.

- A place for everything – in safety terms.

- Management of walkways.

- Awareness and mitigation of trip hazards.

- Awareness of guarding integrity.

- Working at height : safe use of steps, gateways and ladders.

- Safe use of storage racking.

- Safety lock-off systems.

- Systems for managing Fork Lift Truck activity.

- Clear machine instruction labels.

- Labeling of switches & control panels.

- Management of First aid equipment.

- Awareness and contact with 1st Aiders.

- Management of sharps and spill kits.

- Awareness of pipe work contents and flow patterns.

- Management of oil leaks.

- Environmental control measures.

Followed by Group exercise:

Delegates will be divided into groups for an exercise evaluating the current condition of safety systems deployed in their workplace using a simple template the results of which will later be shared with the wider team.

The key outcome of this phase is to get all attendees to develop a prioritised action plan and make measurable and visible changes to the safety standards of the target areas.

The improvements identified will be incorporated into a prioritized Excellence model action plan and will be integrated with the ideas developed during the 5S workplace organization session below.

Throughout this programme only one action plan is developed incorporating all of the improvement ideas from each unit of the training.

In this way the programme can be delivered at a pace that suits the client.

There is no defined timing plan between units – it depends on the resources available to the client to action the improvement ideas.

UNIT 2 :

Organisation and Optimisation of the workplace.

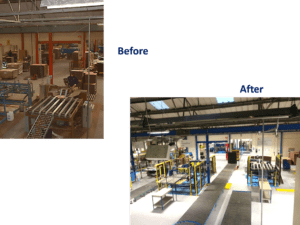

The objective of this training phase is to get the attendees to develop a prioritised action plan based on optimising the layout, storage systems and organisation of the workplace. At the end of this phase we aim to realise measurable and visible changes to the look and performance of the target areas.

Lean concepts to be trained in this session…

i. Developing cleaning and checking schedules and the importance of maintaining them.

ii. Designing the optimal layout for the workplace : making the job easier!

iii. Organising the workplace for maximum efficiency : Runners, visitors and strangers.

iv. Developing the most effective storage methodologies.

v. Introducing Kanban systems for both material control and continued supply.

vi. Developing audit systems to ensure standards are maintained.

vii. The use of Excellence models for managing initiatives : Understanding the importance of having clear aims and objectives.

Throughout this Unit and Unit 1 the teaching resources will rely heavily on using Photographic and Diagrammatic Images (of both good and bad practices) : thus re-enforcing the Visual and Kinaesthetic (Learning by doing) learning methods felt to be the most appropriate approach for this target audience.

Followed by Group exercise:

Delegates will be divided into groups for an exercise evaluating the current condition of systems deployed in their workplace and be encouraged to make suggestions on how these could be improved.

Each attendee will be required to carry out (as part of a team) a 5S Workplace organization audit of their own area using a structured template. The ideas generated are then incorporated into a prioritised Excellence model action plan.

The key outcome of this phase is to get all attendees to develop a prioritised action plan and make measurable and visible changes to the performance of the target areas.

The improvements identified will be incorporated into the action plan developed during the 5S Safety session above.

Throughout this programme only one action plan is developed incorporating all of the improvement ideas from each unit of the training.

In this way the programme can be delivered at a pace that suits the client.

There is no defined timing plan between units – it depends on the resources available to the client to action the improvement ideas.

UNIT 3 :

Advanced asset care : In-your face Engineering.

This course is designed to sit in-between the basic 5S workplace organisation techniques and the more resource-demanding Productive Maintenance approaches.

It is designed to generate low cost/no cost improvement ideas generally based on visual management techniques.

Lean concepts to be trained in this session…

• Marking the proper operating settings and ranges on gauges.

• Effective storage, deployment and management of lubricants.

• Inserting see-through windows on covers of critical equipment to allow their condition to be monitored.

• Marking the proper direction of rotation on motors.

• Labeling replacement belt, filter, and chain sizes.

• Introducing retractable lines to ease access to services.

• Preventing mistakes by effective dial labeling.

• Refusing to tolerate electrical short-cuts.

• Colour-coding set-up and changeover parts for specific jobs.

• Colour-coding pipes and air lines (and their connections) to prevent mistakes from happening.

• Labeling pipes to indicate what they contain and their direction of flow.

• Labeling electrical and electronic wiring and devices to aid troubleshooting.

• Match-marking nuts and bolts to visually indicate that proper tightness is being maintained.

Followed by Group exercise:

Delegates will be divided into groups for an exercise evaluating the current condition of Asset care systems deployed in their workplace and encouraged to make suggestions on how these could be improved.

Each attendee will be required to carry out (as part of a team) using a standard Asset care audit template a (accompanied) survey of their area to identify the opportunities that exist. They will then be required to draw up a prioritised action list.

The improvements identified will be incorporated into the Excellence model action plan.

The key outcome of this training is to provide attendees with an understanding that there exists a range of simple, low cost but very powerful tools for getting the best out of their equipment and realising major cost savings and quality/safety gains.

UNIT 4 :

Introducing robust Visual control systems.

Visual control are means, devices, or mechanisms that are designed to manage or control the operations (processes) so as to make problems, abnormalities, or deviation from standards visible to everyone : thus allowing corrective action to be taken immediately.

Visual control communicates very effectively the information needed for decision making.

Lean concepts to be trained in these sessions…

- Building effective POKA YOKE mistake proofing systems.

- Introducing visual devices, or mechanisms that are designed to manage or control processes.

- Electronic Standard Operating Procedures (eSOPs).

- Virtualization through VR technologies (see unit 5).

UNIT 5 :

Developing agreed, safe and optimised working procedures.

Clear, visual Safe working procedures are the cornerstone of Safe and efficient workplaces since :

- They provide an agreed, defined reference standard.

- It makes People look at What and Why they do things: perhaps for the first time!

- They minimise misunderstanding and miscommunication.

- It provides a vehicle for long running disagreements to be aired.

- It allows for a line to be drawn in the sand: “this is what is inviolable!”

- They provide an excellent training aid.

Where we are in 2024…

Developing State -of-the Art-procedures using Industry 4.0 Techniques.

EXTENDED REALITY (XR) TECHNIQUES.

XR incorporates, among other things, the related technologies of augmented reality (AR) and virtual reality (VR).

AR superimposes digital data on the real world, either through mobile devices like tablets or special head-mounted displays (HMDs).

VR uses HMDs to contain the user in a purely digital world.

Both technologies offer a thrilling glimpse into a future that blurs the line between the physical and digital worlds.

One other term is often used in the context of XR: mixed reality (MR).

Augmented Reality Systems:

Isolated applications of AR have been around for decades, but only recently have the technologies required to unleash its potential become available.

AR transforms volumes of data and analytics into images or animations that are overlaid on the real world.

Today, most AR applications are delivered through mobile devices, but increasingly delivery will shift to hands-free wearables such as head-mounted displays or smart glasses.

Wearable AR devices for factory workers that superimpose production-assembly or service instructions are being piloted at thousands of companies. AR is supplementing or replacing traditional manuals and training methods at an ever-faster pace.

Developing potential VR support systems:

Each attendee will be required to carry out as part of a team a (accompanied) survey of their area to identify the opportunities that exist. They will then be required to draw up a prioritised action list of VR applications.

The improvements identified will be incorporated into the Excellence model action plan

The key objective of this phase is to increase efficiency and effectiveness simply by deliberately making things more visible.

Emphasis is put on incorporating as many visual instructions as possible into the control procedures: thus re-enforcing the Visual and Kinaesthetic (Learning by doing) learning methods emphasised in this programme.

When things are visible, they are kept in the conscious mind. It also serves to ensure that everyone has a common viewpoint of what is being displayed.

Traditional pages on flat screens—have a major limitation – they require people to mentally translate 2-D information for use in a 3-D world.

That isn’t always easy, as anyone who has used a manual to assemble flat-pack furniture knows.

By superimposing digital information directly on real objects or environments, AR allows people to process the physical and digital simultaneously, eliminating the need to mentally bridge the two.

That improves our ability to rapidly and accurately absorb information, make decisions, and execute required tasks quickly and efficiently.

The key outcome of this phase is to get the attendees to develop highly visible process control systems to enhance customer perception of the product and service being provided.

Getting the Team to develop an Operating procedure in this way can be one of the most valuable and beneficial exercises for ensuring consistent and safe working practices.

Methodology :

Each attendee will be required to (as part of a team) generate the first draft of a safe working procedure or their process (in VR form).

- The team then reviews this draft.

- Any procedure improvements are agreed.

- Further review until consensus reached.

- Incorporating as many POKA-YOKE mistake-proofing ideas as possible into current working practices.

- Any ideas for process improvement are recorded and incorporated into the Excellence model action plan.

- The tasks are detailed and systematically broken down into their respective component skill sets.

In this way a detailed analysis is undertaken of the tasks required to do a job in the right way.

Emphasis is put on incorporating as many visual instructions as possible into the VR systems: thus re-enforcing the Visual and Kinaesthetic (Learning by doing) learning methods emphasised in this programme.

Even if safe working procedures already exist for the operation this is still a valuable exercise because it ensures that every operator has studied and reviewed that document.

Training needs analyses are developed for each skill set.