How efficient is your supply chain? :

VALUE STREAM MAPPING

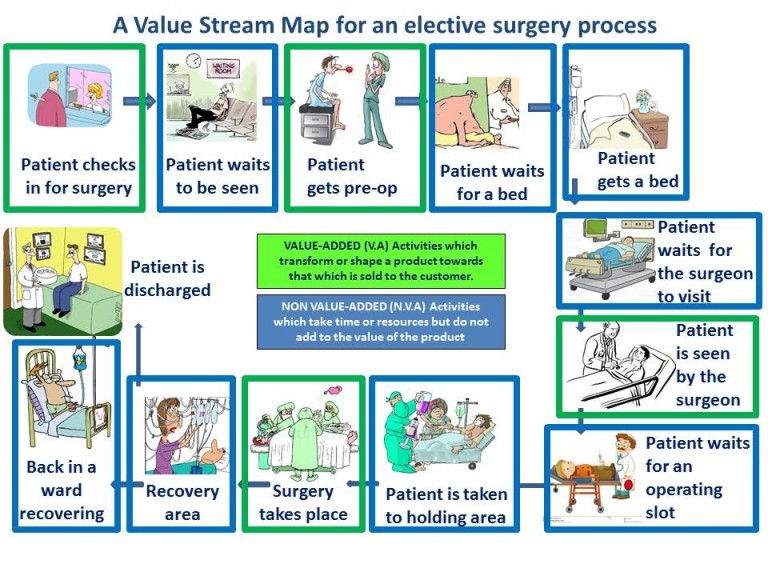

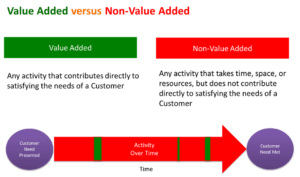

VSM is a tool to visually show all the actions (both value-added and non-valued-added) currently required to bring a product or service through to the customer.

What is the Goal?

To decrease the proportion of time spent not adding value within the business process.

How do we start?

- We map the key business processes to identify what happens at each stage and by whom this is done.

- We then identify the factors…

…that cause bottlenecks and delays in the system.

…and may not be the optimal way of doing things, and give rise to opportunities for improving the efficiency of the process.

What techniques are used for mapping?

Two simple but sophisticated techniques are used to analyse the value-streams :

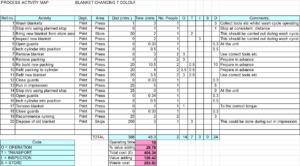

- Process activity mapping.

- Value-Added/Non-value added stream mapping.

The focus is to identify what causes time and effort to be wasted and develop more effective systems and procedures to ensure customer satisfaction and achieve maximum value for money.

What type of processes are examined in this way?

Everything!

For example :

- The design process from concept to product or service launch.

- The customer complaint or return process.

- A manufacturing process from raw material delivery to finished product despatch.

- The commercial transaction process from order capture to cash generation.

- Anything else which involves complex processes and inputs from people!

Take for example, the process of undergoing elective surgery.

The blue boxes indicate where the system could be improved.

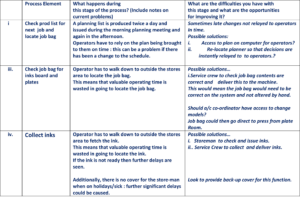

Click on the summary below for a taster of the course content.

Taster of value stream mapping

How is this programme structured for on-line delivery?

A typical on-line training programme in VSM would be structured as follows:

Step 1 : Identify the value-streams you wish to analyse. Allocate an owner (individual or team) to undertake the project for each value stream.

Step 2 : Training session 1 : Process Mapping the value stream

2 hours online.

Step 3 : The individual or team then go away and map the value stream under consideration using the templates (1) provided : 2-3 weeks.

Step 4 : Feedback on mapping work completed, agree an action plan.

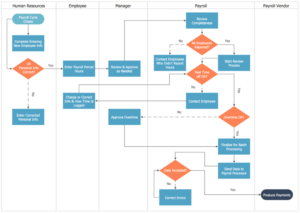

Training session 2 : a study of the cross-functional links in the value stream:

Activity Mapping using the swim-lane technique :

2 hours online.

Step 5 : The Individual or Team go away and develop Activity maps of the target processes using the templates (2) provided : 2-3 weeks.

Step 6 : Feedback on work completed, agree an expanded action plan.

Training session 3 : An in-depth examination of process efficiency: Value–Stream Mapping, focusing on the 8 Wastes of Muda :

2 hours online.

Explanatory notes :

1. Value Stream Mapping (VSM) is a tool to visually show all the actions (both value-added and non-valued-added) currently required to bring a product or service through to the customer (click the image to enhance its clarity).

We map the supply chain to identify what happens and by whom this is done.

We also try to identify the factors…

- That cause bottlenecks.

- That may not be the optimal way of doing things. (Identify MUDA).

The 8 wastes are illustrated in the graphic below: click the image to enhance the clarity.

The 8 Wastes of MUDA graphic:

Step 7: Individual or Team go away and develop detailed Value stream maps using the templates (3) provided : 2-3 weeks.

Final session : Feedback on work completed, agree on finalised action plan :

2 hours online.

Total on-line contact time : 8 hours.

Programme timescale : 8-12 weeks.

Follow up support sessions can then be provided as required.